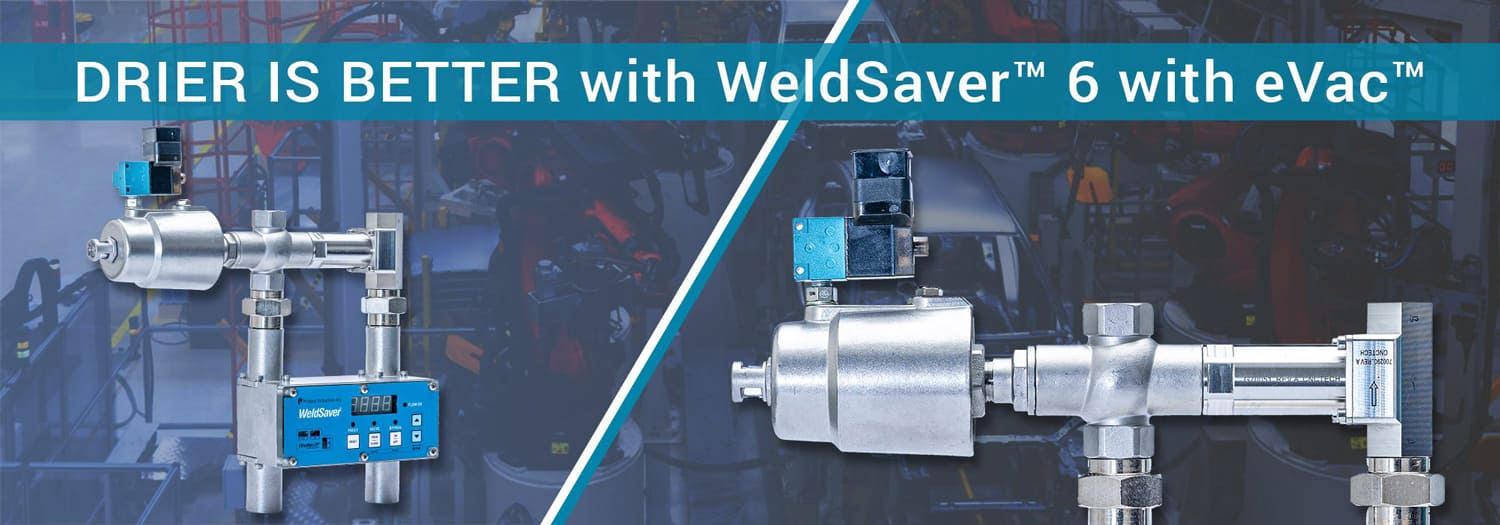

The Proteus WeldSaver™ 6 with eVac™ Coolant Retraction Module is for water control in order to control flow, leak detection and to prevent catastrophic coolant dumps at the time of robotic automotive welding operations.

It has been over 25 years, the Proteus WeldSaver is known as the industry’s leading water control device to control flow and provides the fastest leak detection in automotive welding. By integrating a new with eVac™ Coolant Retraction Module, Proteus adds intense protection against coolant dumps while doing welding operations by retracting water from the cooling gun circuit.

Video courtesy RAM Solutions

The proprietary detection algorithm of the WeldSaver rapidly identifies flow velocity changes, which differentiate true leaks from pressure-, temperature-, and motion-induced effects, identifying a leak condition within 0.3 seconds. In the event of a cap loss or other leak, the WeldSaver signals a state change to immediately in order to stop the welding process, simultaneously closes an attached shutoff valve, and retracts water from the cooling gun.

No matter monitoring coolant flows to weld guns or to the entire weld cell cooling circuit, the WeldSaver with eVac rapidly and reliably observe changes in flow continuity created by slow leaks, cap loss, or other catastrophic events and significantly reduces or prevents coolant dumps on expensive cap-changers and weld cell floors.

Image courtesy of Sinterleghe S.r.l.

Proteus Industries specializes and excels at providing customer requested customization which may include: fittings, special cables and connections, brackets and specialized calibrations including viscosity compensation.

Custom designed for a customer to use in harsh (>1100GHz) EMI or RF environments. The 8000RFR has been laboratory tested up to an RF power of 10v/m to 10GHZ (maximum laboratory testing available). Effective design indicates that this device is capable for up to 1181 GHz.

98008SA6F3P1: Some of our customers require our products to be used under extreme temperature conditions.

For this purpose, Proteus can supply a closed-cell foam insulator to prevent icing in cold conditions or protect workers from burns in higher temperatures.