The Proteus WeldSaver™ is the leading flow control device for leak detection and coolant-expulsion prevention in robotic welding applications. It actively monitors coolant flow to weld guns or to the entire weld-cell cooling circuit and communicates detailed status information to the robot controller or PLC via standard industrial communication protocols. The WeldSaver rapidly and reliably detects changes in flow rate or temperature relative to established set points, and the proprietary detection algorithm can positively identify a leak condition in less than 0.4 seconds. In the event of a cap loss or other break in the coolant flow circuit, the WeldSaver signals to immediately stop the weld process and simultaneously closes an attached shutoff valve.

Protects Expensive Equipment: With Proteus’ NEW innovative eVac™ technology, the WeldSaver continuously retracts coolant from the weld gun in the event of a cap-off or cap change, thereby reducing water damage to adjacent equipment. The eVac Coolant Retraction Module is fully integrated into the WeldSaver operation and firmware, unlike competitors’ offerings. Moreover, the continuous water evacuation provides better protection than competing volume-limited drawback cylinders.

Saves Welds, Reduces CapEx: The WeldSaver can pay for itself with a single use because it prevents bad welds from happening, protects robotic welding guns from overheating, and prevents adjacent equipment from damage caused by coolant expulsion.

Reduces Maintenance Time: The WeldSaver can cut maintenance visits for weld-cell clean-up because it reduces water on the floor and on costly equipment thanks to its fast and reliable automatic shutoff of coolant flow when a leak is detected.

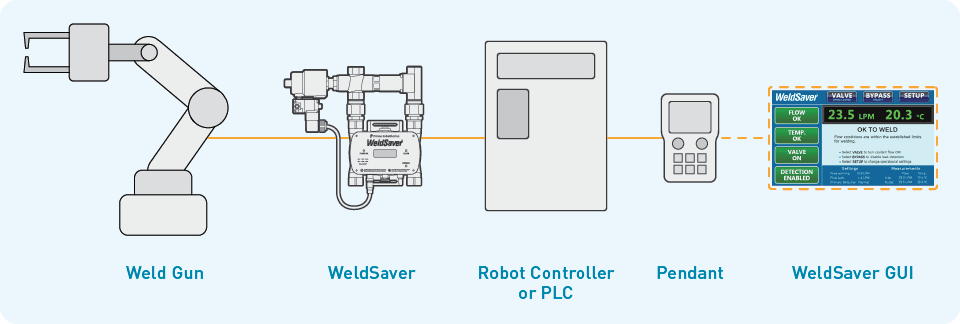

Weld-Cell Integration: The WeldSaver communicates with your robot controller or PLC using industry-standard I/O data formats, making integrations streamlined. Customized bit-mapping may be available for your specific requirements.

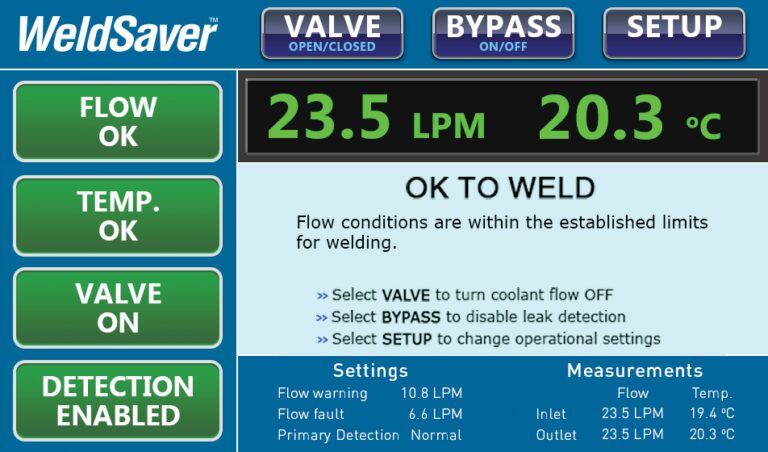

Industry-Leading Graphical User Interface: The WeldSaver offers a state-of-the-art web-based GUI for easy setup and control. Critical information can be displayed in real time on any Javascript™-enabled browser. The control capabilities and information display are far more intuitive and robust than a simple keypad alone.

Teach Pendent Compatible: The real-time status indication and control capabilities of the WeldSaver GUI are fully compatible with popular teach pendants for easy setup and operation.

Count on Proteus: For over 25 years, leading automotive OEMs have depended on Proteus Industries’ WeldSaver technology to monitor critical cooling circuits, detect leaks and cap-loss, and automate valve shutoff —reliably and automatically. Now, with the NEW eVac Coolant Retraction Module to evacuate coolant away from the weld circuit, Proteus is delivering even more value to its automotive robotic welding customers. Call Proteus today to learn how we can enhance the efficiency and protection of your system!

Proteus Industries specializes and excels at providing customer requested customization which may include: fittings, special cables and connections, brackets and specialized calibrations including viscosity compensation.

Custom designed for a customer to use in harsh (>1100GHz) EMI or RF environments. The 8000RFR has been laboratory tested up to an RF power of 10v/m to 10GHZ (maximum laboratory testing available). Effective design indicates that this device is capable for up to 1181 GHz.

98008SA6F3P1: Some of our customers require our products to be used under extreme temperature conditions.

For this purpose, Proteus can supply a closed-cell foam insulator to prevent icing in cold conditions or protect workers from burns in higher temperatures.