The importance of accurate flow measurement

In the world of process controls involving fluids, accurate flow measurement is a critical aspect of operations. Whether in the semiconductor equipment, automotive, medical, or industrial markets, understanding the basics of flow meters is critical to ensuring efficiency and cost-effectiveness in your processes. So, let’s dive into the fundamentals of flow meters and discover how they can ensure accuracy in your applications.

At its core, a flow meter is a device used to measure the rate and quantity of fluid passing through a system or pipe. It provides crucial data that helps in decision-making, optimization, and maintaining the overall operational performance of systems and processes. But how do flow meters achieve this?

The first step in understanding liquid flow meters is knowing the different types available. Liquid flow meters come in various forms, such as paddlewheel flow meters, vortex flow meters, differential pressure flow meters, electromagnetic flow meters, ultrasonic flow meters, and positive displacement flow meters. Each type has its unique operating principles and is suitable for specific applications.

Paddlewheel flow meters use the mechanical energy of the liquid to rotate a paddlewheel (just like a riverboat) in the flow stream. Paddles on the rotor transform energy from the flow stream into rotational energy. Magnets in the rotating paddlewheel create a frequency signal (Hz) that transmits to the meter’s electronics, where it may be converted to a user-friendly analog output such as 0-5VDC of 6000 series flow meter, 0-10 VDC, or 4-20 mA. Alternatively, the user may prefer to use the basic Hz signal. Turbine flow meters operate in a similar manner.

A vortex meter, such as the PV6000 Series vortex flow meters and V7000 Series Vortex flow meters, is a type of volumetric flow meter that uses a natural phenomenon that occurs when a liquid flows around a bluff body. Vortex flow meters operate under the vortex shedding principle, where vortices (or eddies) are shed alternately downstream of a bluff body. A piezoelectric element senses the vortices and transmits a frequency signal (Hz) to the meter’s electronics. The electronics can retransmit the Hz signal directly or convert it to a user-friendly analog output.

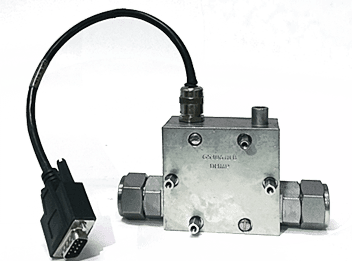

Differential pressure flow meters, for example, measure the flow rate by calculating the pressure difference between two points in the system. They work on the principle that as fluid flows through a pipe, the pressure decreases due to factors such as friction and obstructions. By measuring this pressure difference, differential pressure flow meters can determine the flow rate accurately.

Electromagnetic flow meters use Faraday’s law of electromagnetic induction to measure the flow rate of conductive fluids. These meters rely on a magnetic field and electrodes placed in the pipe. As the fluid flows, it induces a voltage in the electrodes, which is directly proportional to the flow rate.

Ultrasonic flow meters, as the name suggests, use ultrasonic waves to measure the flow rate of liquids. They employ the principle of the Doppler effect or transit time difference to calculate the flow velocity. By transmitting ultrasonic waves through the fluid and analyzing the change in frequency or time it takes for the waves to travel, ultrasonic flow meters can determine the flow rate accurately.

Positive displacement flow meters measure the flow rate by capturing and counting discrete volumes of fluid. These meters consist of rotating or reciprocating elements that divide the fluid into known volumes. By measuring the frequency or displacement of these elements, positive displacement flowmeters can accurately determine the flow rate.