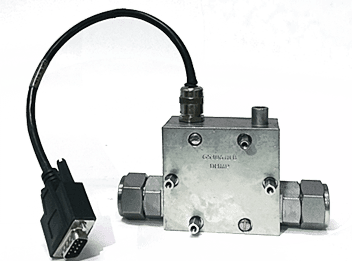

Proteus WeldSaver™

The Proteus WeldSaver™ is a specialized device to detect cap off conditions on robotic welders. The first “water saver” to use modern computing techniques to detect cap-off’s, the WeldSaver™ is now used by many major automotive companies and their sub-tier suppliers.

Installation and Maintenance Information

- Install the WeldSaver™ to avoid problems when flushing pipes.

- Adjustment of Control Settings.

- DeviceNet interface.

- Servicing Valves.

- Replacing Electronics.

A research paper provided by the courtesy of Unitrol discusses the importance of controlling cooling flow in resistance welding.

Click here to download the paper in .pdf format. Click here to go to Unitrol’s website.

WeldSaver™ is a registered trademark of Proteus Industries Inc. DeviceNet is a registered trademark of ODVA.