Solid State Sensing Technology

Consider Proteus Industries for innovative solid-state sensing technology based on vortex technology. As demands for more sophisticated data collection rise, transitioning from traditional flow switches to advanced flow meters like the 6000 series flow meter, PV6000 Series vortex flow meters, and V7000 Series Vortex flow meters has become essential. And since most flow system also require temperature, switching to a 2 in 1 meter for both flow and temperature is the most economical way to proceed. A commonly asked question from prospective OEM’s is simply, can you help me with the justification. Here are a few ideas you can use, and naturally exact justification calculations will be highly dependent on the actual use case.

Increased Functionality

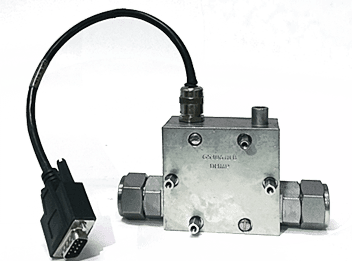

Most flow systems today use flow switches, which function simply as an interlock – the machine won’t run unless flow is present. However, having the ability to monitor the exact flow rate and turn machines into Industrial Internet of Things (IIoT) devices has tremendous value. By monitoring everything, there is less that can go wrong, and predictive maintenance can be enabled. With Proteus Industries vortex based meters, you can monitor flow, temperature and even pressure from the same device, increasing the amount of monitoring and further reducing what can go wrong.

Reduced Maintenance Costs for you and your customers

The solid-state design of the PV6000 Series vortex flow meters and V7000 series vortex flow meters ensures an extended lifespan and high resilience against suspended solids. Unlike their mechanical counterparts, solid-state measuring there are no moving parts and thus less to go wrong. This, in turn, means maintenance will be less for end users, and there will be fewer returns from customers which need to be processed.

Better Performance

With improved data comes the ability to better optimize the cooling process. Balancing flows across several channels, ensuring some flow circuits get more flow than others because they are more critical, knowing exactly when parts of the machine could be overheating. Machine performance can only be optimized with more information as a baseline.

Less Downtime

Leveraging the lower maintenance and the predictive maintenance enable less downtime and more product produced. Less downtime means metrics are available to show higher level of productivity, and the ability to sell machines for more money, or at a minimum – defend requests for price reductions.

Minimal Cost Impact

Moving from a plastic flow switch to a plastic flow meter, or a metal flow switch to a meter flow meter, is not a significant difference in purchase price. Compared to the value of the additional information provided, for many applications, the justification is relatively easy. Often the direct per unit cost increase can be offset by fewer plumbing and electrical connections, as well as the improvements mentioned above.

So, while a switch just might be enough and do the trick, think about switching to a meter and let your machines enjoy the IIoT revolution.