Thermal Control Flow Meters – Die Casting

Proteus flow meters are used to improve die life, startup scrap reduction and productivity

Proteus flow meters are used to monitor flow and temperature at both the inlet and the outlet of die coolant flow channels. Die casters use the data provided by Proteus flow meters to control initial heat ramp, calculate heat loads, ensure sufficient cooling, optimize thermal control, and protect against coolant channel blockage.

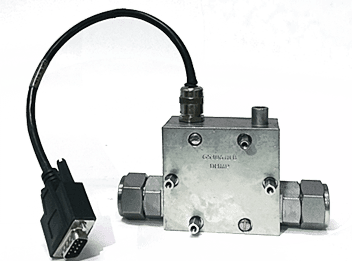

The Proteus V7000 Series Vortex Flow Meters and the 8000 Series Liquid Flow Meters are both well suited for die coolant monitoring. The new microprocessor based V7200 Series affords better accuracy and the capability to connect directly to your digital fieldbus.

Integrate Proteus flow meters to your existing die casting process

Integrate Proteus flow meters to your existing die casting process. Talk to us about customizing the V7200 Series meter to incorporate distributed processing and control.

Recommended flow meters for die casting –V7000 Series Vortex Flow Meters the 8000 Series Liquid Flow Meters, and the new networkable V7200 Series flow meter.

Please contact Applications Support at tech@proteusind.com or (650) 964-4163 for more information.

Full thermal process control solutions – Die Therm Engineering

Die Therm Engineering provides process solutions for the thermal control challenges faced by the die casting industry.

Die Therm Engineering, headed by long-time die casting expert and consultant Scott Kirkman, has developed a thermal control scheme utilizing both advanced software and the latest smart hardware from Proteus to deliver unparalleled benefits to the die casting industry:

> Improved Design Process

> No Thermocouples

> Rapid Die Start-up

> Monitor & Control Heat During Production

> Reduced Cycle Time

> Dimensional Accuracy

> Eliminate Machining

> Greatly Decreased Scrap

> Reduced Die Wear

> Longer Die Life

> Reduced Down Time