Flow Measurement System Finds Alternative Applications

The original plan was to develop a flow measurement and control system with leak detection and energy-use calculations for liquid-cooled supercomputers at the Lawrence Livermore National Laboratory. The outcome included applications for military vehicles and other harsh environments, as well as calibration with liquid flow rates at temperatures from -80 C to 240 C.

3 Original Designs

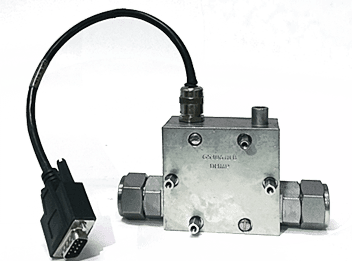

For the semiconductor industry, a 200 C liquid flow rate sensor was planned and designed (see 200 C section on page SS-6.) For the automotive industry, a reduced size with vortex or paddlewheel-turbine sensors and one or two communications ports for Ethernet, Profinet,

DeviceNet protocols were planned and designed (see WeldSaver section on page SS-5). For the fastest supercomputer at the time (2012), the Coolant Monitor was planned and designed with IBM, (see Coolant Monitor on this page).

A Surprise Phone Call from the Army

Sometimes a phone call makes all the difference. One such phone call came from a deployed, mobile Army Missile Control Center. The outcome was the examination of the actual use of a product versus the published product specification. The result of the examination review was to create a harsh environment product specification and conduct a related test plan. The critical consideration was that the product was being used in an unintended application, and lives were potentially at stake. Obviously, there was a need for a product that didn’t exist and wasn’t specified. It wasn’t “build it and they will come,” but rather, “they came, and we shall build it.” A Mil-Std 810 Test Plan was developed and conducted. This activity had many lessons

Read full article HERE

Proteus Industries

Richard Fertell, M.S.C.S.