8000XHT Operate at High and Low Temperature

Some of our customers require our products to be used under extreme conditions.

Proteus can supply a closed-cell foam insulator to prevent icing in cold conditions or protect workers from burns in higher temperatures.

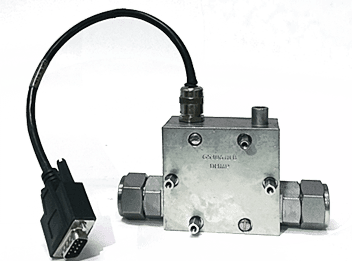

The 8000XHT series flow meter provides an accurate, reliable, and cost-effective measurement of heat transfer fluids and other liquids. It is a revolutionary breakthrough in flow metering devices that deliver superior precision and reliability in flow and temperature measurement for critical heat-sensitive processes.

The 8000XHT has a unique operational mechanism that depends on embedded alternating magnets. The magnets (north and south) spin as the water flows through the sensor cavity, creating a spin in the rotor that transfer pulses through two flux concentrators to switch the two Hall-effect sensors mounted on the main electronics board. A microcomputer is embedded in the 8000XHT that monitor the rotational frequency of the rotor, scaling the factors into a flash memory to calculate the volumetric flow rate. The flow rate information is measured at an output between 0-10 or 0-5 VDC and 4-20 mA.

The 8000XHT has an adjustable relay trip point, programmed to change the state when measured outflow is below a preset alarm value. The tricolor LED on the device gives a visual indication of the liquid flow status. To ensure accuracy and to prevent unwanted tampering, each device comes with an alarm trip point, preset by the factory. The factory setting for upper flow limit is 15%; however, customers can request a customized trip point setting at the time of order.

Mil-Std 810 Ruggedized Applications

The 8000XHT Series – Custom designed to use in rugged applications as well as difficult EMI or RF environments (400A Magnetic Power Field or >188 GHz @ 10V/m) and with high-temperature fluids to +200C. The 8000XHT has been laboratory tested to Mil-Std 810 Method 514.5 – 514C-2 for 2 wheeled composite trailer with Shock to 20G.

Cost-effectiveness

The 8000XHT offers the capability to measure the liquid flow rate and temperature with a single instrument and only requires a single connection point in the entire pipeline. Customers also have an option device, i.e., Pt1000 Resistance Temperature Detector (RTD) probe that is mounted in the sensor body and provides a direct measurement of liquid temperatures between -80 to 200 degrees Celsius (-112 to 381 Fahrenheit).

Flow Sensor Specifications

> Output Formats Voltage: 0–10 VDC (default) or 0–5 VDC • Current: 4–20 mA

> Fluid Temperatures – Standard1 10 to 200 °C / 50 to 392 °F

> Fluid Temperatures – Extended1,2 -80 to 200 °C / -112 to 392 °F

> Ambient Temperature1 -40 to 75 °C / -40 to 167 °F

> Operating Pressure Limit 1724 kPa / 250 psi

> Burst Pressure (5:1) 8618 kPa / 1250 psi

> Pressure Drop Less than 69 kPa / 10 psi at the maximum flow rate

> Accuracy – Standard ± 3% of flow range with standard validation

> Accuracy – Validated ± 2% of a calibration value

> Linearity ± 1.5% of flow range from 0.1 to 1.0 × flow range

> Repeatability ± 1% of flow range from 0.1 to 1.0 × flow range

> Hysteresis 5% of flow range

> Input Power Voltage +24 VDC ± 10%

> Input Power Consumption < 1 W

> Relay Contacts Maximum Current 1 A at 48 VDC

> Voltage Output Maximum Sourcing Current 15 mA at 2 VDC output

> Maximum Loop Resistance 900 Ω at 24 VDC

> RF-immune Stainless-Steel electronics enclosure. The standard enclosure does not have Status LED availability.

> The functionality of the meter will not be affected by RF power of 10V/m to 10GHz (Maximum laboratory testing result) at enclosure cover and body face.

> Wetted Materials Flow body: Cast 316 stainless steel Rotor: PPS

> O-ring: FKM (Viton®) Rotor shaft: 316 stainless steel

> Enclosure Protection NEMA 4X • IP66

> Cable Connection M12 male 8-pin connector

> Standards and Compliance CE conformity • RoHS and REACH compliance

Technical Specifications

> Flow ranges from 0.95 to 60 LPM / 0.25 to 16 GPM

> Accuracy of 3% of full scale

> Optional temperature measurement from -80 to 200 C / -112 to 392 °F

> Low-Temperature Operation Option with fluid temperature as low as -70˚ C

> Specialized calibration to account for viscosity effects of fluid and operating temperature

> Enhanced accuracy and stability from digital signal processing

0–5 VDC or 0–10 VDC and 4–20 mA outputs

> Standard NEMA 4X / IP66 enclosure

> Customization available for OEMs

> 5-year warranty

Temperature Sensor Specifications

> Sensor Type Pt1000 RTD probe (DIN EN 60751 Class A)

> Measurement Range -80 to 200 °C / -112 to 392 °F

> Output Format Resistance

> Output Value 0 °C = 1000.0 Ω • 10 °C = 1039.0 Ω • 125 °C = 1758.6 Ω

> Accuracy ± 0.15 °C at T = 0 °C

> Wetted Materials Probe housing: 316 stainless steel

> Lead Wires 3-wire • 30 AWG • PTFE insulation • Length: 3.0 m / 118.5 in

Documentation

> Data Sheet

> Setup Guide

> 8000XHT Series Solid Works

> Online Ordering

Proteus has provided value-added product customization for our customers for over 30 years. Our sensors, meters, and switches are used worldwide in many industries, including solar, medical, and automotive. These products protect thousands of induction furnaces and robotic welders, with applications expanding to high-power laser and plasma cutting and semiconductor processing systems. All of our products can be customized to fit the application.

Proteus has an ISO 9001 certified quality system.

Our flow switches, meters, and sensors are backed by our five-year warranty.

For detailed product inquiries, please contact Mark Malfatti at M_Malfatti@proteusind.com