How can I know if fluid is chemically compatible with my flow sensor?

A Series of Articles designed to help customers in their liquid flow system applications using Proteus Industries flow products.

The importance of materials chemical compatibility: Fluid vs. sensor’s wetted materials.

Q: How can I know if my fluid is chemically compatible with my flow sensor?

A: If your fluid is unrefined ambient temperature water, this is generally not a time-intensive process.

However, with temperate extremes, deionized water, highly polished water, water with coolant mixes and additives, and exotic thermal fluids, research should be invested to determine the liquid’s chemical compatibility with your Proteus flow sensor.

The internet is an indispensable research tool in this regard. Manufacturer’s data sheets and product guides can be a good source of information. A quick concept is to simply refer to the other materials used in the engineered components of your flow system: depending on the original design intent, simply following suite is generally a safe bet.

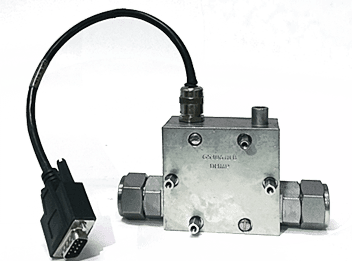

But there is more: besides knowing your fluid and your system component’s materials, you must also know your sensor’s “wetted materials”, i.e., all of the sensor’s internal components that will be exposed to the flow stream and fluid. The sensor’s flow body and internal components are not always constructed of the same material. There are often supplemental materials and o-rings. Consult the Proteus Industries data sheet for a full list of your sensor’s wetted materials. Each item must be checked for compatibility with your fluid.

Besides the above strictly chemical compatibility issues there are other compatibilities to consider:

- Electro-chemical compatibility. For example, a stainless steel flow body should NOT be connected with a brass system fitting and vice versa. Galvanic corrosion can occur.

- Mechanical compatibility: Coefficient of thermal expansion mis-match and over-tightening mechanical stress/strain (i.e. cracking) can occur when metal piping (particularly NPT threads) is installed to plastic flow bodies (particularly molded plastic flow bodies).

- Higher temperatures and pressures generally enhance bad effects.