Flow Meters And Switches For OEM

Proteus offers free samples of standard Proteus-manufactured flow switches or flow meters for evaluation in new applications by prospective OEM customers. Proteus flow meters and switches monitor cooling flow and other liquids in industrial applications.

Please see the full list of flow products below.

100 Series Flow Switches

> Flow rates from 0.2 to 227 LPM / 0.06 to 60 GPM

> Adjustable trip point

> Flow switch cannot jam in Flow OK position

> 5-year warranty

More DETAILS

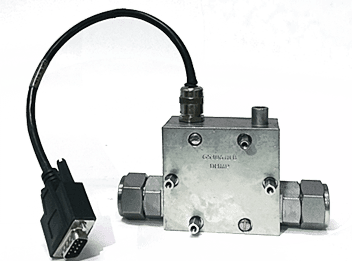

500 Series Metering Flow Switches

> Flow ranges from 0.8 to 17 LPM / 0.2 to 4.5 GPM

> Liquid temperatures from -40 to 140°C / -40 to 284°F

> Pressure to 1723 kPa / 250 psi

> Calibrated 0–5 VDC output

> Relay trip point – 16 preset settings

> Compact design

> Customization available for OEMs

> 5-year warranty![]()

More DETAILS

800 Series Metering Flow Switches

> Flow ranges from 0.2 to 227 LPM / 0.05 to 60 GPM

> Liquid temperatures from -40 to 140°C / -40 to 284°F

> Pressure to 1724 kPa / 250 psi

> Calibrated 0–5 VDC output

> Relay trip point – 16 preset settings

> Compact design

> 5-year warranty![]()

More DETAILS

Extreme-Temperature Flow Meters – 8000XHT

Innovative technology and design, for use with fluid temperatures to 200 °C

> Flow ranges from 0.95 to 60 LPM / 0.25 to 16 GPM

> Accuracy of 3% of flow range

> Optional temperature measurement from 10 to 200 °C / 50 to 392 °F

> Specialized calibration to account for viscosity effects of fluid and operating temperature

> Enhanced accuracy and stability from digital signal processing

> 0–5 VDC or 0–10 VDC and 4–20 mA outputs

> Standard NEMA 4X / IP66 enclosure

> Customization available for OEMs

> 5-year warranty![]()

More DETAILS

PV6000 Series Vortex Flow Meters

> Flow ranges from 0.9 to 85 LPM / 0.2 to 22 GPM

> Accuracy of better than 3% of flow range

> Liquid temperatures from -40 to 100°C / -40 to 212°F

> Rugged glass fiber-reinforced PPA construction

> No moving parts – performance is not affected by contaminants in fluid!

> 0–10 VDC or 4–20 mA analog output or pulse output for easy interfacing with your PLC

> Optional integrated temperature sensor

> Optional digital display

> IP65 enclosure

> Customization available for OEMs![]()

More DETAILS

V7000 Series Vortex Flow Meters

> Flow ranges from 1.8 to 150 LPM / 0.48 to 40 GPM

> Accuracy of better than 3% of flow range

> Optional temperature measurement from -40 to125 °C / -40 to 257 °F

> Optional pressure measurement from 0 to 1200 kPa / 0 to 174 psi

> Pulse, resistance, 0–10 VDC or 4–20 mA outputs

> 3/8″ to 1¼” FNPT, MNPT, or SAE connections

> Rugged stainless steel construction

> Flow response can be calibrated for kinematic viscosities from 0.3 to 14 cSt – traceable calibrations also available

> No moving parts – high resistance to suspended solids

> Optional digital display

> IP65 enclosure

> Customization available for OEMs![]()

More DETAILS

FluidVision USB™ and Temperature Flow Meters

> Connects flow sensor directly to a computer via standard USB port

> Electronics and paired flow sensor are powered by USB port—no auxiliary power supply needed!

> Compatible with V7000 Series and PV6000 Series vortex flow meters with pulse output

> Multiple programmable alarm levels for both flow rate and temperature

> Includes specialized software for system monitoring and data-logging

> 5-year warranty![]()

Free sample for OEMs

To request a free sample, please fiil out the form below describing your application needs or email us directly at tech@proteusind.com with “Free Sample” in the subject line. Please be sure to include your name, the name of your company, the address to which the sample should be sent and your telephone number. You may also call Mark Malfatti or David Chiasson at (650) 964-4163.