How Long of an Inlet and Outlet Tube do I Need on My Flow Meter

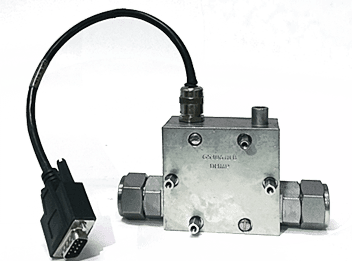

This is a very common question in regard to installing new flow meters such as the 100 Series Flow Switches, 800 Series Metering Flow Switches, 8000 Series Liquid Flow Meters, 8000XHT Series Extreme-Temperature Liquid Flow Meters, or the 8000EMR Series flow meters. The answer depends on the type of flow sensor technology employed. In this article, we will look only at paddlewheel type flow sensors. With this type of meter, the inlet is the most sensitive and critical to the performance of the flow meter. For example, if there were an elbow attached directly at the inlet, there would be an excessive amount of turbulence induced into the rotor cavity. The accuracy of the flow reading will be affected. Measurements have shown that the accuracy may be affected by as much as 3%.

To maintain an accurate reading, it is recommended that a straight length equal to 10 pipe inner diameters be installed at the inlet of the flow meter. The outlet tube length does not have the same degree of consequence, but a straight run of at least 3 pipe inner diameters is recommended.

Another solution to this issue is to request the manufacturer to install the fittings and calibrate the meter with them in place. This nullifies the error factor.

In another article we will discuss the use of fittings and tubing and how they can affect accuracy.