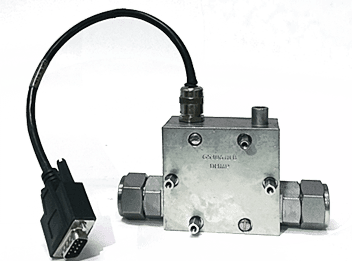

8000XHT -80C to +200 Extreme Temperature Flow Meters

> Design to operate in high EMF (Electro Magnetic Field) environments

> Built to work in HARSH environments

Innovative technology and design, for use with fluid temperatures up to 200 °C

> Flow ranges from 0.95 to 60 LPM / 0.25 to 16 GPM

> Accuracy of 3% of flow range

> Optional temperature measurement from 10 to 200 °C / 50 to 392 °F

> Specialized calibration to account for viscosity effects of fluid and operating temperature

> Enhanced accuracy and stability from digital signal processing

> 0–5 VDC or 0–10 VDC and 4–20 mA outputs

> Standard NEMA 4X / IP66 enclosure

> Customization available for OEMs

> 5-year warranty

![]()

Contact Us

Detailed product inquiries: Sales@proteusind.com

Technical inquires: Tech@proteusind.com

Phone: (650) 964-4163